Description

PVC ceiling sheets

PVC Foam Ceiling Sheet,which is a sheet – shaped material and mainly made of PolivinylClorua (denoted as PVC) along with some inorganic additive, is applied to make concealed and exposed ceiling.

.jpg)

Technical specification:

- Standard size: 1220 x 2440 x 5mm

- However, for the exposed ceiling, Picomat comes up with the following size:

The standard size for exposed ceiling: 605 x 605 x 5mm and 605 x 605 x 8mm

- Density: 0.45 g/cm3

- Color: White. In addition, Picomat offers PVC film combined with PVC Foam Ceiling Sheet in order to create afaux wood ceiling system with a range of aesthetically pleasing colors.

With our respect, love towards human life and an orientation for sustainable development, environmental and social friendliness, Picomat provides customers with PVC Foam Ceiling Sheet- a new line of material for interior decoration with outstanding features: completely water resistant, superior durability, anti – termites, anti – mould… PVC Foam Ceiling Sheet is widely used in fit-outs of office, residential, hospital, school…

Especially, PVC Foam Ceiling Sheet is a “green” product line, safe for health and does not contain toxic like formaldehyde, sulfur, lead…which has been certified to E1 European and RoHS standard.

Technical

PVC ceiling sheets

.jpg)

1. Hard and smooth surface

It is a critical criterion that designers, architects are interested in and make decision.

2. Paint on the surface of PVC Foam Ceiling Sheet

PVC Foam Ceiling Sheet can be directly painted on the surface which is glossy and smooth to be suitable with oil – based paint.

3. Complete water resistance

PVC Foam Ceiling Sheet,which is completely impervious to water, is able to prevent moisture transferred via osmosis and does not promote pathogen caused by damp habitat.

.jpg)

4. Anti – termites

The main raw material is PVC thermoplastic, therefore, PVC Foam Ceiling Sheet is absolutely anti – termites.

5. Green material

Not only is PVC Foam Ceiling Sheet environment – friendly and recyclable but it is also harmless to users as its main component is PVC thermoplastic.

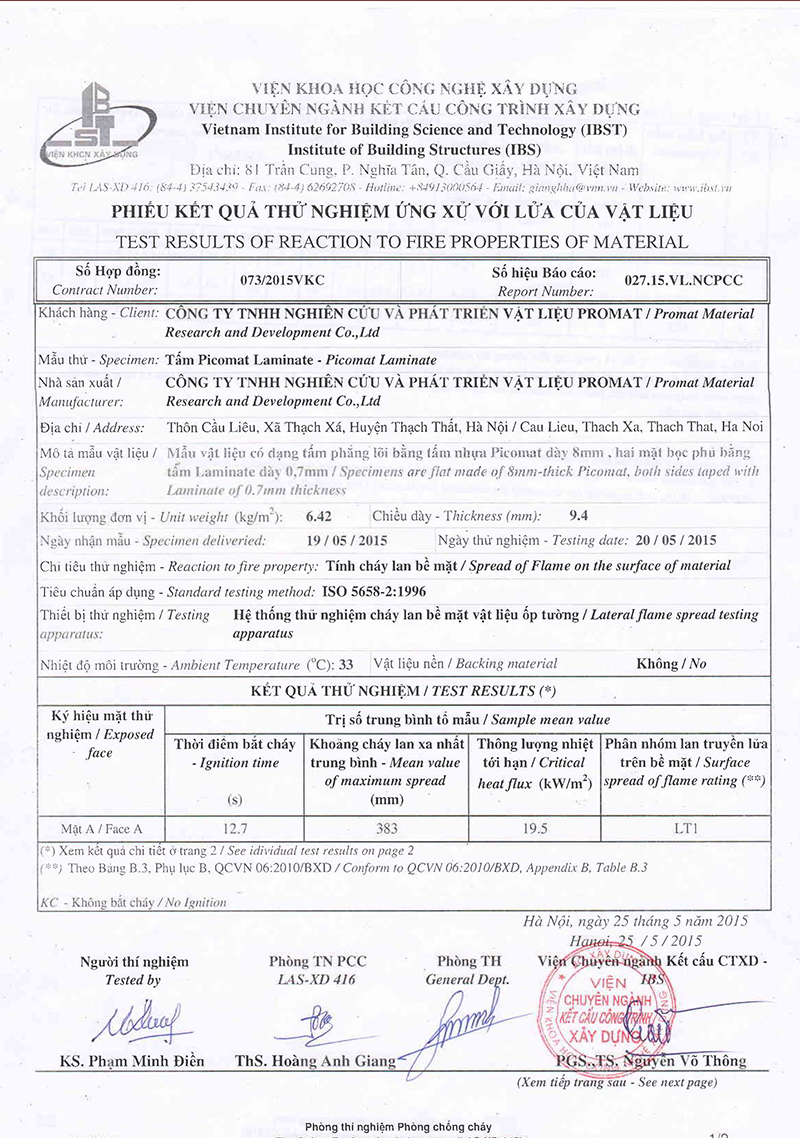

6. Fire retardant

PVC Foam Ceiling Sheet is able to suppress or delay the production of flame to prevent the spread of fire with the purpose of dragging on time so that residents can evacuate safely.

.jpg)

7. Superior durability

Designers/ constructors choose Picomat’s products for the purpose of safety and warranty in that PVC Foam Ceiling Sheet’s life cycle is 30-40 years and highly resistant to extreme environment of slight alkalinity and acid, high humidity, seawater.

8. Simple fabrication

Processed by traditional woodworking tools, PVC Foam Ceiling Sheet can be used to create concealed, exposed and faux wood ceiling system.

9. Cost – saving

PVC Foam Ceiling Sheet saves time and cost in the process of soaking, drying, UV spraying, surface flattening. Furthermore, the fabrication of PVC Foam Ceiling Sheet does not release as much dust as that of natural wood.

Online Support

Online Support